Porous Diffusion Layer - Electrochemical Core Materials

Ti-Ni Material Expert | Four Product Series | Highly Customisable

Product Overview

Porous diffusion layers are critical components in electrochemical systems, essential for water electrolysis, fuel cells, and electrochemical synthesis. As transport media for gases and liquids, they require excellent conductivity, corrosion resistance, and controlled porous structure.

echemstore offers four series of porous diffusion layer materials: titanium felt, nickel felt, high-performance nickel mesh, and high-performance foam nickel to meet diverse electrochemical application requirements.

Core Advantages

- Material Diversity: Four material series covering high-performance titanium and nickel

- Highly Customisable: 50-90% porosity, 0.2-6.0mm thickness, flexible sizing

- Superior Performance: Excellent conductivity, corrosion resistance, and mechanical strength

- Wide Applications: Suitable for PEM/AEM electrolysers, fuel cells, chemical filtration

Product Series

Four series of porous diffusion layer materials meeting diverse electrochemical application requirements with superior performance and high customisation

Titanium Felt Series

Echemstore titanium felt uses advanced sintering technology with micron-level titanium fibres, featuring 3D mesh structure and gradient porosity design, delivering superior electrolysis efficiency and exceptional durability in harsh environments.

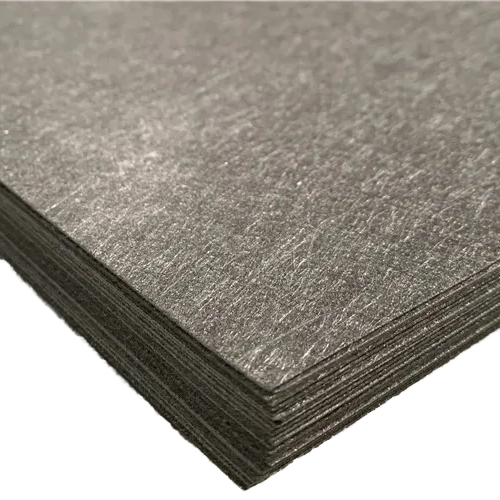

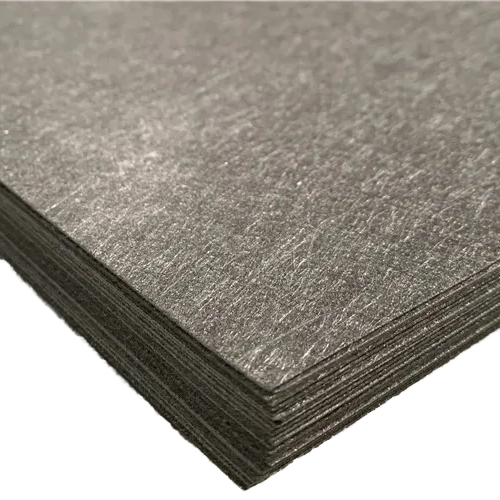

Nickel Felt Series

High-purity nickel fibres (Ni≥99.5%) sintered into 3D porous material, designed for high-performance electrochemical applications with exceptional corrosion resistance and durability in harsh environments.

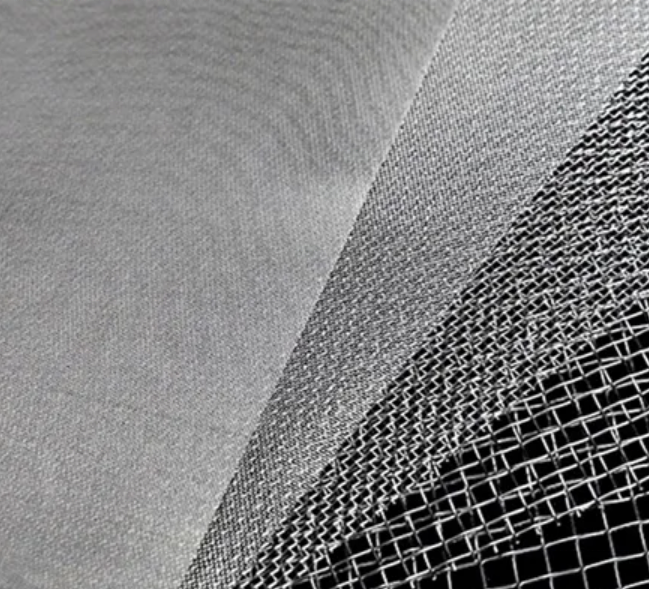

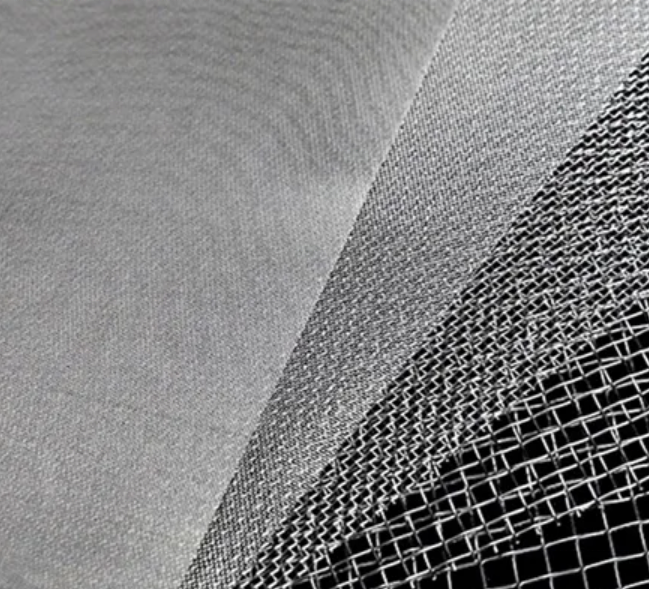

High-Performance Nickel Mesh Series

Premium N4 (99.9% Ni) and N6 (99.6% Ni) alloys with excellent corrosion resistance, thermal stability, and conductivity for demanding industrial applications.

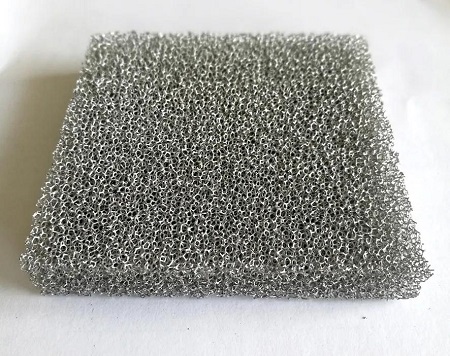

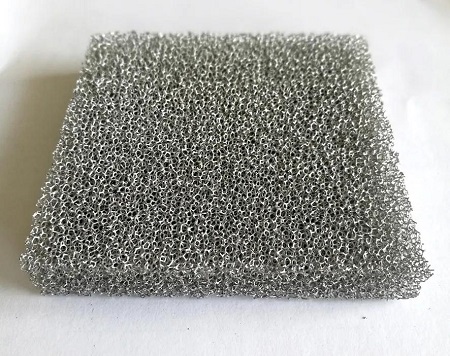

High-Performance Foam Nickel Series

Manufactured through electrodeposition, high-temperature oxidation, and hydrogen reduction processes, featuring unique structural and functional properties for electrolysis, battery electrodes, and catalyst applications.