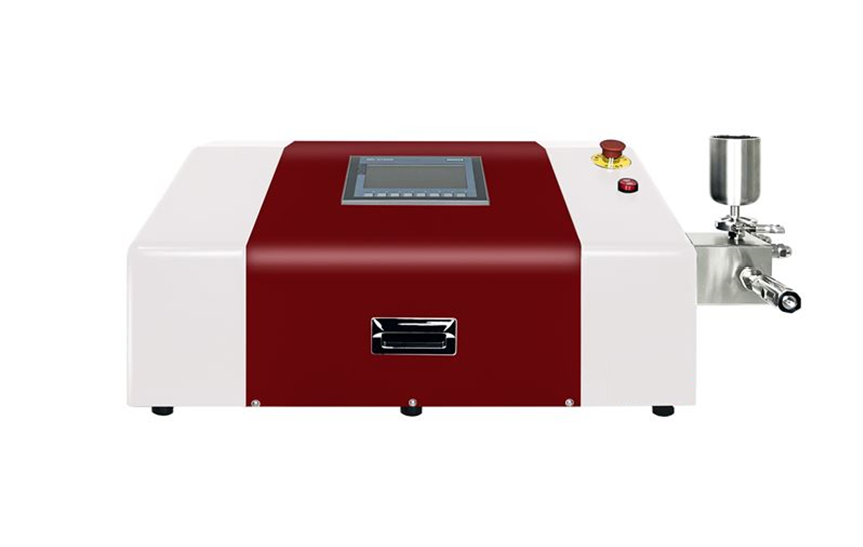

Microfluidic Nano Homogenizer

Diamond Interaction Chamber · Nano-level Precision · Pharmaceutical Grade Quality

Product Overview

The echemstore Microfluidic Nano Homogenizer EQ-HG-01 features advanced diamond interaction chamber technology (Y/Z type), generating supersonic microfluidic jets at pressures up to 60,000 Psi for pure physical nanoparticle dispersion. Widely used in pharmaceuticals (liposome preparation), cosmetics (nano-encapsulation), energy (graphene exfoliation), and biotechnology (cell disruption), it's ideal for lab-to-industrial scale production.

Core Microfluidic Technology: The high-pressure homogenizer consists of a high-pressure homogenization chamber and pressurization mechanism. The chamber features specially designed geometry that subjects materials to high-speed shear, high-frequency oscillation, cavitation, and convective impact under high pressure, along with thermal effects. These mechanical and chemical effects induce changes in the physical, chemical, and structural properties of large molecules, achieving homogenization.

Key Features

- Nano-level Precision: Particle size reduction from 500μm to 0.74nm, polydispersity index PI < 0.03

- Diamond Interaction Chamber: Y-type for emulsion preparation, Z-type optimized for particle crushing, coolable design

- FDA-Compliant Materials: 316L stainless steel, titanium alloy, tungsten carbide, pharmaceutical grade standards

- Smart Control System: Touchscreen interface, real-time pressure/flow monitoring, automatic stop protection

- Linear Scalability: Seamless scale-up from 5mL lab samples to industrial production

Core Technical Advantages

Nano-level Precision

Particle size down to 0.74nm, polydispersity index PI < 0.03, ensuring excellent dispersion

Diamond Interaction Chamber

Advanced Y/Z-type diamond interaction chamber, ultra-high pressure microfluidic technology, pure physical dispersion

Multiple Model Options

Four models available: Nano15k-45k, pressure range 15,000-45,000 Psi, meeting diverse needs

Cross-Industry Applications

Suitable for pharmaceuticals, cosmetics, energy, biotechnology and other fields for nanomaterial preparation

Product Specifications

echemstore offers four different pressure-grade microfluidic nano homogenizer models to meet various needs from laboratory R&D to industrial production.

| Parameter | Nano15k | Nano20k | Nano30k | Nano45k |

|---|---|---|---|---|

| Maximum Pressure | 15,000 Psi | 20,000 Psi | 30,000 Psi | 45,000 Psi |

| Flow Rate | 120 mL/min | 120 mL/min | 110 mL/min | 65-120 mL/min |

| Minimum Sample Volume | 1 mL | 1 mL | 1 mL | 1 mL |

| Operating Temperature | 80°C | 80°C | 80°C | 80°C |

| Power Supply | 110/220/230V | 110/220/230V | 110/220/230V | 110/220/230V |

| Cleaning Method | Flush cleaning | Flush cleaning | Flush cleaning | Flush cleaning |

| Display Function | Digital pressure display | Digital pressure display | Digital pressure display | Digital pressure display |

Standard Configuration Details

Core Components

- Core Chamber: Y-type diamond interaction chamber (coolable)

- Control System: High-pressure program control system®, touchscreen operation

- Pressure Gauge: Built-in high sanitary grade pressure sensor (no dead volume)

- Inlet: 20mL syringe

- Outlet: 20mL syringe

Material Standards

- Main Material: 316L stainless steel

- Wear-resistant Material: Tungsten carbide

- Sealing Material: Fluoroelastomer, PTFE (polytetrafluoroethylene)

- Tubing Material: Polyethylene

- Certification Standards: Pharmaceutical grade, FDA & GMP certified

Control Functions

- Speed Control: Adjustable flow rate control

- Monitoring Display: Real-time flow/pressure display and recording

- Auto Protection: Automatic stop (volume/time control)

- Safety Features: Overload protection, non-destructive pressure relief valve

- Injection Function: Set volume injection

Warranty Service

- Warranty Period: 1-year manufacturing defect warranty

- Technical Support: Professional technical team support

- Training Service: Operation training and maintenance guidance

- Spare Parts Supply: Long-term spare parts supply guarantee

Optional Configuration Options

We offer various optional configurations for different application needs, enabling personalized equipment customization.

Chamber Selection

- Z-type Chamber: Optimized for particle crushing (e.g., graphene exfoliation)

- Homogenization Valve: Suitable for high-viscosity samples

Feed System

- Syringe Specifications: 10mL, 50mL, 100mL, 200mL, 500mL

- Online Feeding: Continuous feeding system

Additional Equipment

- High-pressure Extruder: Special sample processing

- Heat Exchanger: Temperature control system

- CIP/SIP System: For GMP production

Corrosion-resistant Upgrade

- Titanium Alloy Check Valve: Spring-free design

- Titanium Alloy High-pressure Cylinder: Acid and alkali corrosion resistant