Electrolytic Cell - Multi-Chamber Electrochemical Equipment

Flexible Configuration · Precision Manufacturing · Custom Solutions

Product Overview

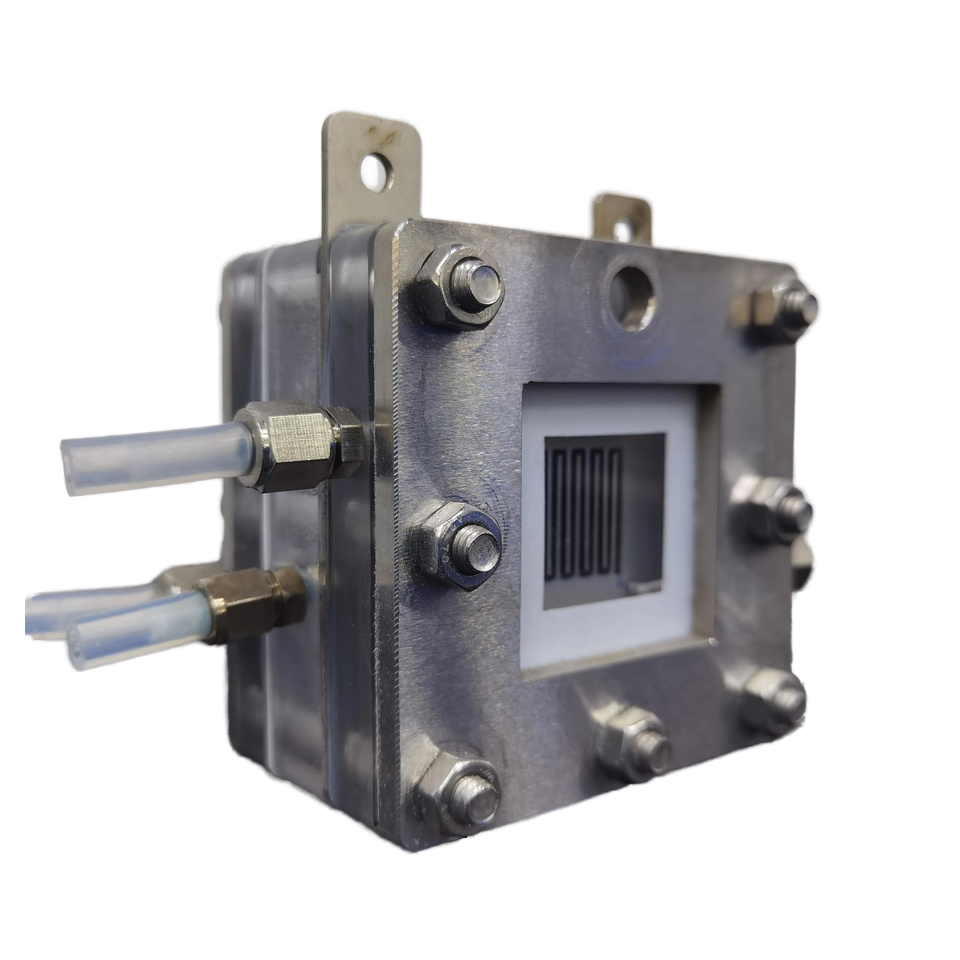

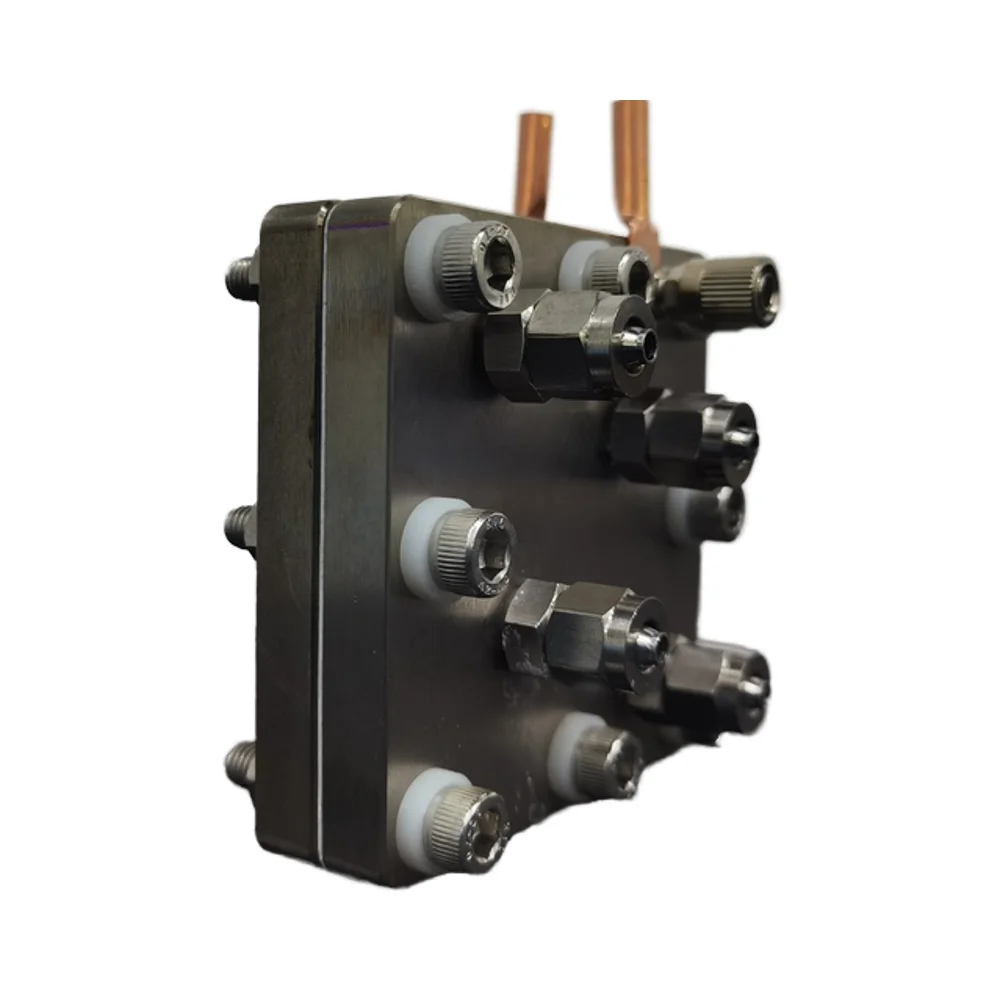

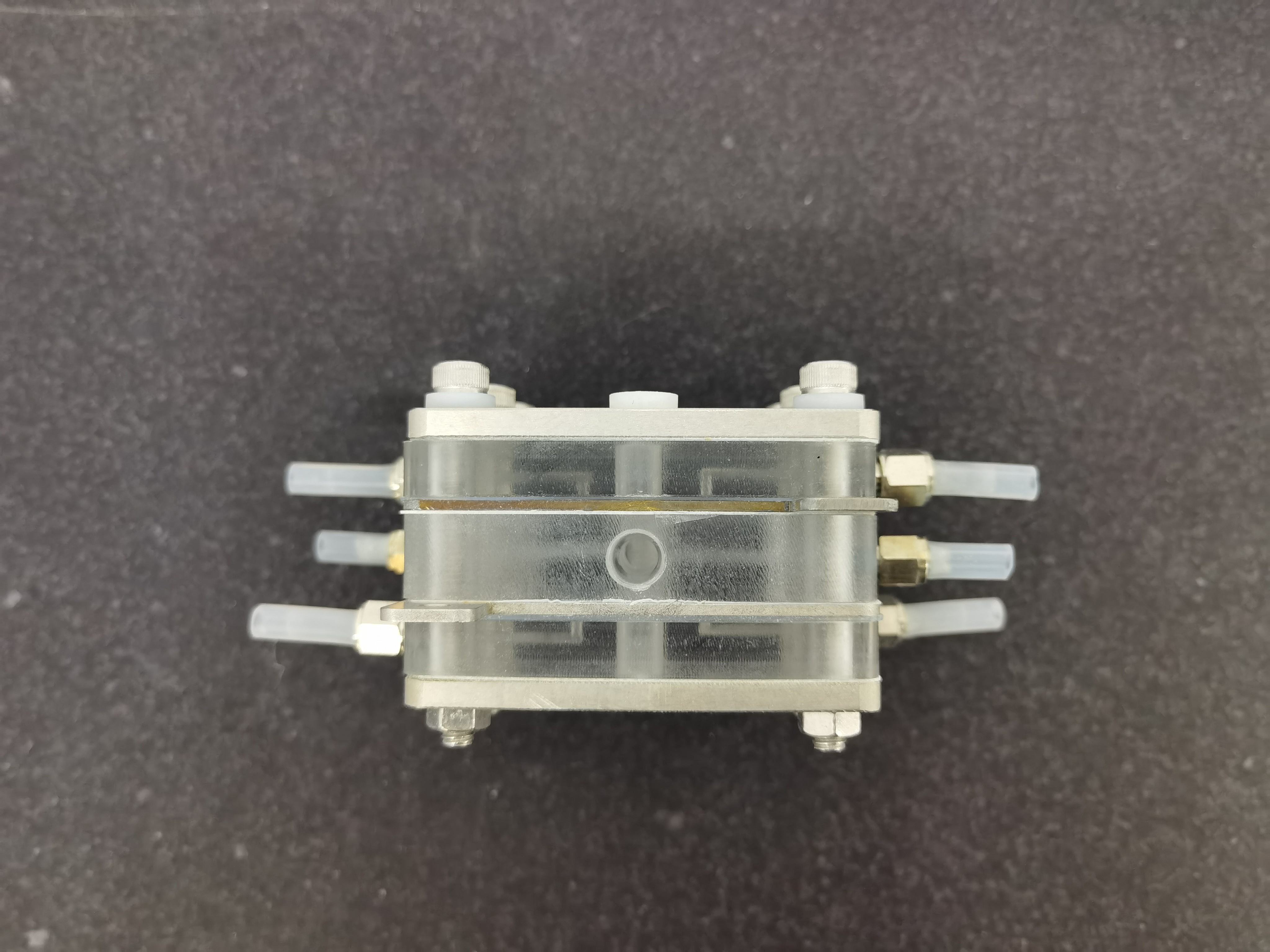

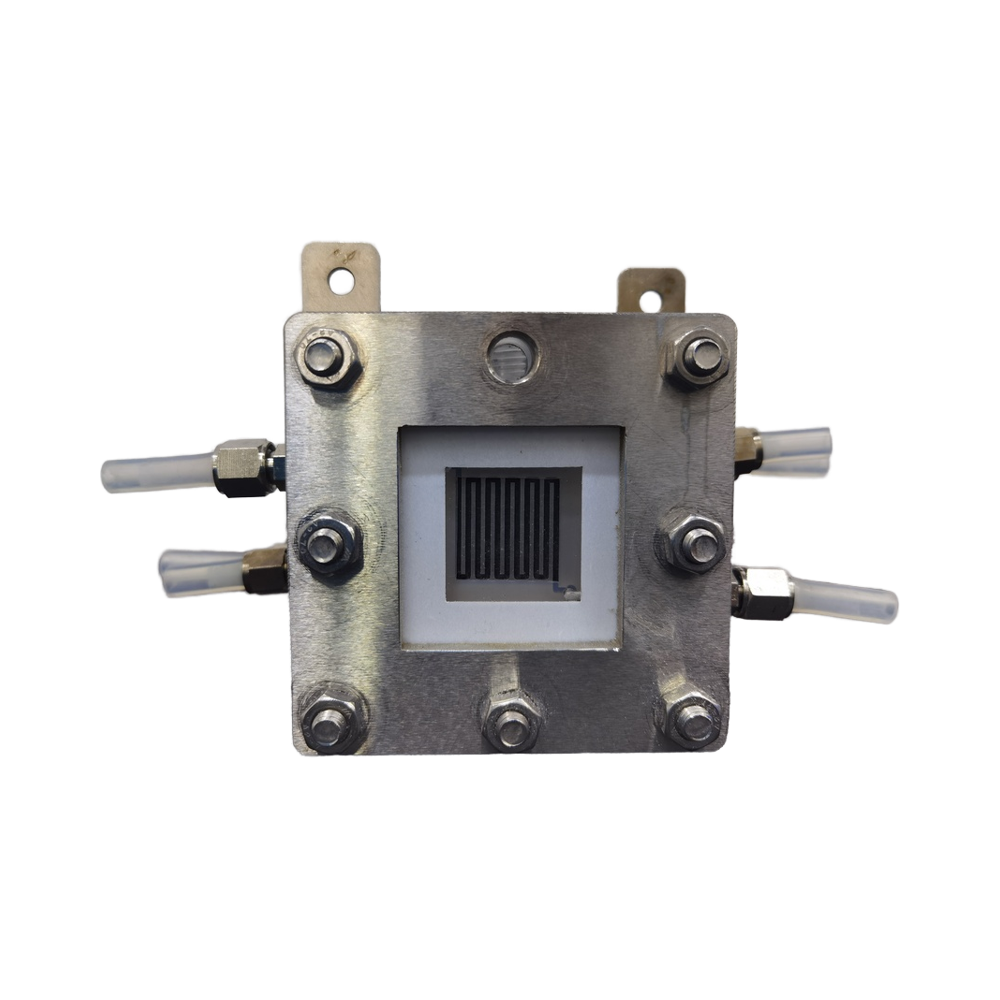

Precision-engineered electrolytic cells with CNC machining for leak-proof sealing. Dual/triple chamber configurations, optional temperature control, customizable reaction areas 1×1cm²~5×5cm².

Key Features

- Multi-chamber design: Dual/triple chamber options

- Temperature control: ±0.5℃ accuracy

- Customizable: Reaction area, materials, flow channels

- Versatile applications: Research to industrial use

Configuration Options

Chamber Structure

Dual Chamber: Separate anolyte/catholyte compartments

Triple Chamber: Additional reference electrode compartment

Temperature Control

Standard: -20°C~80°C operating range

Controlled: ±0.5℃ precision

Reaction Area & Materials

Area: 1×1cm²~25cm² customizable

Materials: PMMA/PTFE, 316L steel, nickel, titanium

Connections & Flow Channels

Connections: Standard 1/4" Swagelok fittings

Flow Design: Serpentine/parallel patterns available

Core Advantages

Precision Manufacturing

CNC machining ensures leak-proof sealing and reproducible results

Enhanced Mass Transfer

Optimized flow channels improve reaction efficiency

Visual Monitoring

Transparent windows enable real-time reaction monitoring

System Compatibility

Versatile design supports MEA and three-electrode systems

Applications

Energy Applications

- Green hydrogen production

- Flow battery testing

- Fuel cell research

Environmental & Carbon Utilization

- CO₂ reduction research

- CO₂-to-fuel conversion

- Carbon capture & utilization

Chemical Synthesis

- Organic electrosynthesis

- Catalyst evaluation

- Reaction mechanism studies

Research & Testing

- Laboratory testing

- MEA validation

- Multi-electrode research